Lack of Lubrication

How often should I lubricate the bearings?

This is a question we often hear. As you are probably aware, there are a lot of variables to consider when deciding how often you should lubricate a bearing. The following is a formula that may be useful in figuring out how much lubricant should be put in a bearing. We like it because it's very simple and direct.

(((Bearing diameter in inches x breadth in inches) x 1.29) / 7) = Daily cc's of lube

This formula is very simple and does not take into consideration a lot of factors.

These types of formulas will get you close. however, they are not perfect, over and under lubrication can still occur.

|

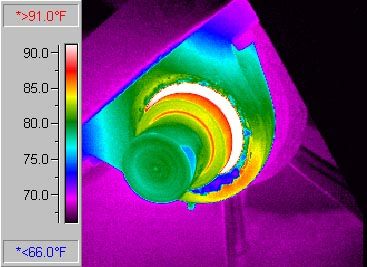

Over lubrication: As a bearing is over lubed it will generate high temperatures. These high temperatures can easily be identified using contact and non-contact temperature gathering methods.

| Infrared shows hot bearing due to Lack of Lube |  |

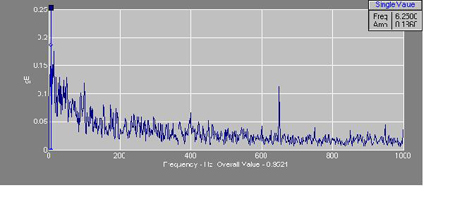

Under lubrication: This fault is not as easy identified, that is to say, without using a more advanced technology. DEMSY use an advanced technology that, not only easily identifies lack of lubrication, but also identifies the severity..